AUTOMATIC CAPSULE FILLER RAA-9/8/7

Features and functions:

- With the patent technology of totally enclosed patent technology in the working table, it solves the inconvenience of dismantling and washing moulds, and the problem of adjusting mould precision.

- The dose adjusting device adopts stand adjusting patent technology, which can conduct trim the dose under no—stop state.

- Adopting the lower can structure in the working table revolution. It has good lubrication results and low wear and tear and prolonging the service life of the parts.

- The adoption of microcomputer control technology makes the machine safe and advance. And enhances the automation control technology makes the machine safe and The set material discharge device maintains the material in the storage room in a fixed height thus ensuring the accuracy of dose.

- The use of import computer, electrical appliances and bearings make the control and transmission system stable in performance and reliable in technology.

- There is no dead comer in the three ends of every group of segment hole of metering disc, which further improve the accuracy of dose with its many—year—experiences in manufacturing field.

Main Technical Parameters:

| Machine model |

RAA-9 |

RAA-8 |

RAA-7 |

| Max capacity |

72000 capsules/hour |

60000 capsules/hour |

54000 capsules/hour |

| Suit for capsule size |

00#-5#and safety capsule |

00#-5#and safety capsule |

00#-5#and safety capsule |

| No. of mould bores |

9 |

8 |

7 |

| Machine dimensions(mm) |

800x1000x1800 |

800x1000x1800 |

800x1000x1800 |

| Net weight |

900 Kg |

900 Kg |

900 Kg |

| Power |

380/220V 50/60Hz 6kw |

380/220V 50/60Hz 6kw |

380/220V 50/60Hz 6kw |

| Vacuum |

40m3/h-0.02-0.05MPa |

30m3/h-0.02-0.05MPa |

30m3/h-0.02-0.05MPa |

| Dust Exhaust |

300m3/h 2x10P5a |

300m3/h 2x10P5a |

300m3/h 2x10P5a |

| Noise |

<75dB |

<75dB |

<75dB |

Products

Our product category

Company information

- Richmech Industrial Co.,Ltd.

- TEL : 886-2-2502-2949

- FAX : 886-2-2505-0192

- Contact Person : Allen Chen

- richmechids@yahoo.com.tw

Sitemap

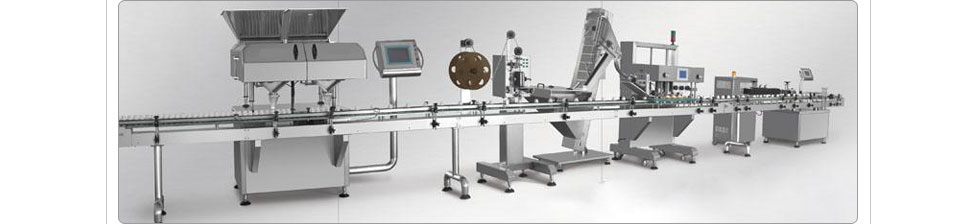

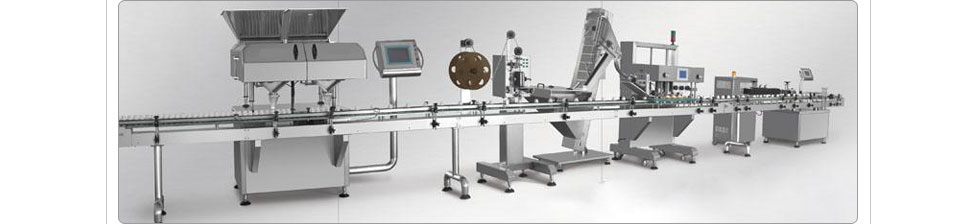

Automatic Tablet Counting Line Automatic Liquid Filling Capping Line