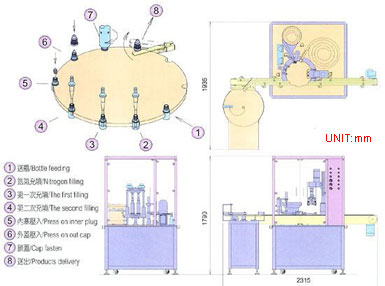

Vial liquid filling/plugging/cap sealing machine RLVC-60

- Feature:

- Adopt single axle adjusting piston, the request filling volume can be adjusted quickly and precisely.

- The part of the piston and cylinder which contacts with the liquid is made of fineceramics. Can avoid the contamination and meet the GMP standard.

- Automatic feeding bottle, positioning and operation are controlled automatically.

- The automatic capping is designed according to the sealing mouth of screw cap.

- With safety device, machine will stop automatically when bottle fell down in star wheel or not in correct position during use the hand-wheel.

- When specification of the bottle is changed. It only needs so change star-wheel. The height can be adjusted also. It is very easy to wash & clean.

- Adopt stepless speed variation motor, the operation speed can be adjusted freely.

- It can be run individual or connected with automatic labeling machine and automatic cartoning machine to complete the whole line running in one line production.

- The Monoblock machine is designed for automatic filling, inner plugging and over-capping onto small containers, most suitable for vial small volume injectable liquid production to meet with GMP standards.

Application:

Suitable for eye-drop bottle, cosmetic, pharmaceutical chemical vial small injection liquid filling, plugging and over-capping operations.

Suitable for eye-drop bottle, cosmetic, pharmaceutical chemical vial small injection liquid filling, plugging and over-capping operations.

- Specification:

- Model Type : RLVC-60V

- Filling Volume : 2c.c~20c.c, 15c.c~40c.c, 30c.c~60c.c, 50c.c~100c.c

- Speed : 35-60 bottles/min.

- Motor : 1HP & 60W

- Air Pressure : 5-6kg(Perpared by buyer)

- Compress air : Consumption:70 L/min

- Electric Power : 220V, 50/60 Hz, single phase

- Machine Dimension : (L)2315mmX(W)1935mmX(H)1790mm

- Machine Weight : 800kgs

- Turn-Table bottle automatic feeding. (Maximum:60OX100H Minimize:26OX56H)

- Optional Devices:

a. Nitrogen filling.

b. Safety hood, meet GMP standards.